The process of creating metal parts has advanced significantly over the years, and one of the most important techniques used is open die forging. This method involves hammering or pressing a heated metal billet between two flat dies to shape it into a specific form. The resulting product can be used for a variety of applications and industries, including gear manufacturing.

Recently, the Chinese forging company, Quanzhou Dena Machinery Technology Co., Ltd., has highlighted the importance of open die forging in the production of half-finished ring gears. Ring gears are critical components in many machines, including automotive transmissions, wind turbine generators, and industrial machinery. These gears are circular in shape and have teeth along the edge, allowing them to mesh with other gears and transmit torque.

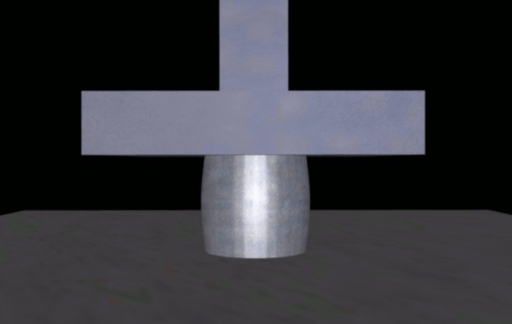

To produce these gears, manufacturers often use open die forging to start the process. The heated metal billet is placed on the bottom die, and the top die is lowered to form the initial shape of the gear. This process is repeated several times, with the metal being rotated after each hammering to create the final shape.

Using open die forging to create half-finished ring gears has several advantages over other manufacturing methods. First, the process produces a product with superior strength and durability compared to other techniques like casting or machining. This is because the forging process aligns the metal's internal grain structure along the shape of the gear, resulting in improved strength and durability.

Second, open die forging is a flexible manufacturing technique. Ring gears come in different sizes and shapes, depending on the application. The open die forging method can create various ring gear sizes easily and quickly, making it an ideal manufacturing process for different industries.

Third, open die forging produces less waste than other manufacturing methods. With casting, for example, the mold used to create the gear is discarded after each use. This can lead to more waste and higher costs. In open die forging, the metal is shaped into the gear's final form, so there is minimal waste created.

Quanzhou Dena Machinery Technology Co., Ltd. produces a variety of gears for different industries, including bucket bushings, bucket pins, and swing/travel part gears, as well as planetary carrier ass'y, ring gears, shafts, cases, gearboxes, and slewing ring bearings. Their focus on open die forging and half-finished ring gears ensures their customers receive high-quality products that offer superior performance and durability.

Qingdao Hexin Machinery Co., Ltd., another forging company based in China, is also well-known for its open die forging capabilities. They specialize in producing various types of forging parts, including half-finished ring gears, using open die forging methods.

In conclusion, the use of open die forging in the production of half-finished ring gears is an important technique for many industries. The process produces high-quality parts that are strong, durable, flexible, and have minimal waste. Companies like Quanzhou Dena Machinery Technology Co., Ltd. and Qingdao Hexin Machinery Co., Ltd. have recognized the importance of this manufacturing technique, and their focus on producing high-quality half-finished ring gears using open die forging reinforces its continued significance in the manufacturing industry.